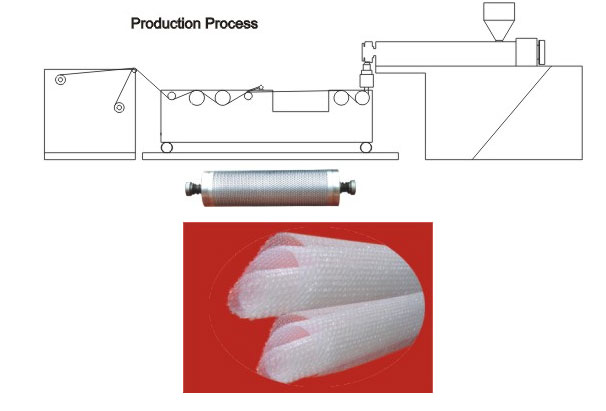

This machine adopts once-through shaping technique, thus has high efficiency and excellent product quality.

BRIEF:

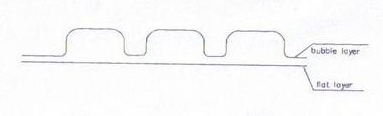

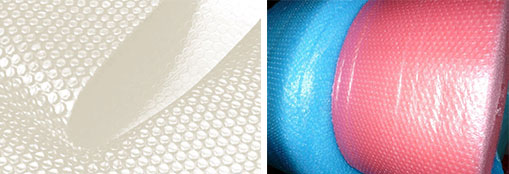

This machine adopts once-through shaping technique, thus has high efficiency and excellent product quality. This machine set has such features as scientific and reasonable structure design, smooth and reliable running and convenient operation and maintenance. Polyethylene air-cushion film (also called polyethylene bubble film), which is divided into two kind: ordinary polyethylene air-cushion film and composite polyethylene air-cushion film, is a kind of packing material which has been widely used at present. It not only has good cushioning effect, shock resistance and heat-sealing performance, but also has such advantages as good corrosion resistance and transparency, etc. So it has been widely used for packing, household wares, post parcel, bicycle, polyurethane furniture, etc.

Material: LDPE

You can use new material, also can use recycled material.

If you want to produce color bubble film, you can add color masterbatch.

Optional Equipments:

1) Auto Loader

2) Auto Dryer

3) Motorize Net Changer

4) Air Shaft

Main Technical Variables:

| Model | GDPE-1000 |

| Diameter of Screw Stem | φ60 mm |

| L/D Ratio of Screw | 28:1 |

| Material of Scerw & Barrel | 38 CrMoALA |

| Width of T-die Head | 1150 mm |

| Heating Way | Casting-aluminum heating device |

| Width of Bubble Roller | 1080 mm |

| Width of Products | 1000 mm |

| Thickness | 0. 06-0. 25 mm |

| Main Motor | 15 kw |

| Tractiong Motor | 1.1 kw*2 |

| Total Power | 30 kw |

| Rewinder | Turnover duplex turret rewinding type |

| Max. Output | 50 kg/h |

| Linear Speed | 1000 m/h |